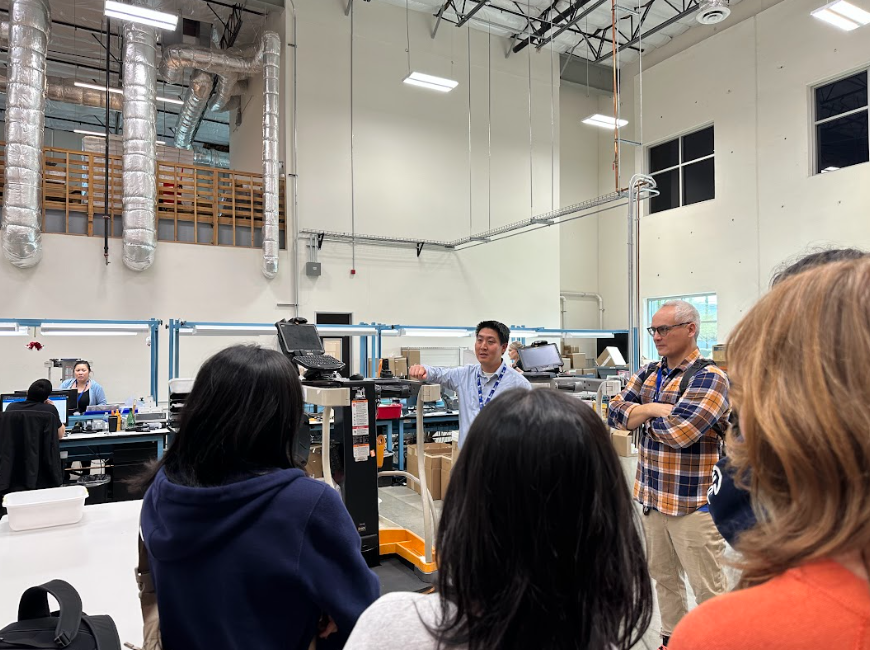

On Dec. 13, select Gabrielino High School students in the physics curriculum toured the GlenAir Arcadia Logistics Center, one of the company’s manufacturing facilities in California. The three hour tour allowed students to get a firsthand experience of the engineering industry through an explanation of GlenAir operations and a closer look at the manufacturing floor.

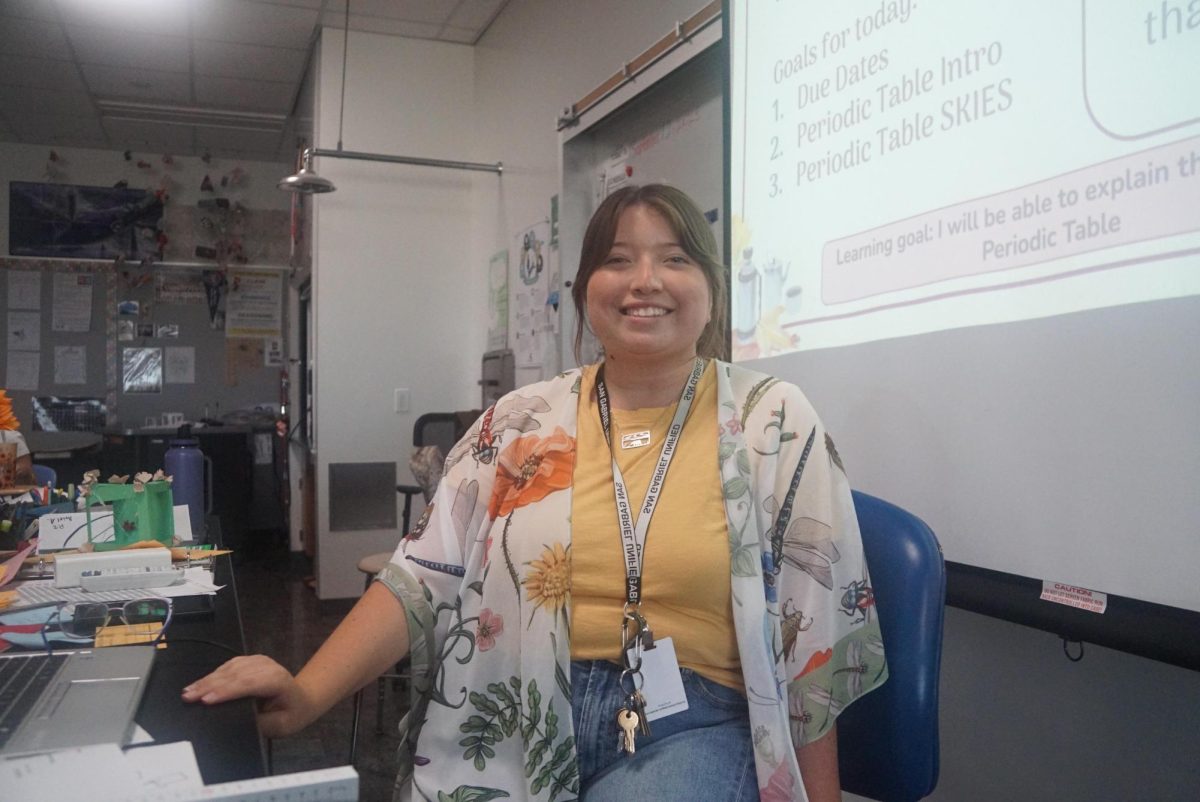

“I wanted kids to see what engineering meant in the real world. It is essentially about making things and when I discovered my former student was an engineer,” stated physics teacher Kevin McClure, who also chaperoned students during the tour. “I asked him to come talk to the kids about engineering. He then suggested we have a field trip and the rest is history.”

GlenAir is a privately owned company based in the United States, making high-reliability connectors and cables for land, sea, air, and space operations. With an emphasis on military aerospace, the company brands itself as having fast “turnaround” and reliability in both manufacturing and customer service.

“I’ve never really been in a manufacturing facility before. I’ve been to biology labs but I would like to explore the engineering aspect of my interests,” stated senior Emma Kurniawan. “I also wanted to see how engineering can be applied to the industry as a job.”

Before allowing participating students to view the work floor of the warehouses, Program Director Shawn Grady and Senior Product Manager Ali Yassine presented information about the company, with topics ranging from specific projects that the company has been part of, why GlenAir is so trustworthy within the manufacturing industry, and the history of the brand.

“The best part of the trip for me personally was probably the presentation and meeting workers who were actually passionate in their field,” stated junior Julissa Pena. “I wanted to learn more about the function of their products and design process behind making them, and I felt that I definitely did through this opportunity.”

Grady and Yassine’s catchphrase to students was “We’re big into that!” when explaining the wide range of projects GlenAir has worked on, such as defense systems, space walks, Mars rock retrievals, fighter jets, and submarines.

“You don’t get a lot of hands-on experience in classes that you get to see with a real manufacturing facility, like with the production side of the facility for example,” stated senior Cindy Tran. “I think I definitely got a better look at what engineering really is before we even got to tour the floor.”

Following the end of the presentation, students were split up into tour groups to get a closer look at daily operations at the manufacturing facility. Unlike many other major manufacturing companies within the industry, GlenAir is unique in that they keep warehouses stocked with their inventory of products; a method that allows the company to sell at a premium for convenience and speed of acquisition.

“I hope kids can see that the world of engineering is multifaceted and holds lots of potential,” said McClure. “I believe field trips can be invigorating and paradigm shifting. Learning the reality behind your dreams can make you see things in a whole different light. Also field trips are just fun. They do cost a lot of money and it is only through the kindness of GlenAir were we able to have this one.”